Wisconsin Aluminum Foundry: Local Expertise in Aluminum Casting

Wiki Article

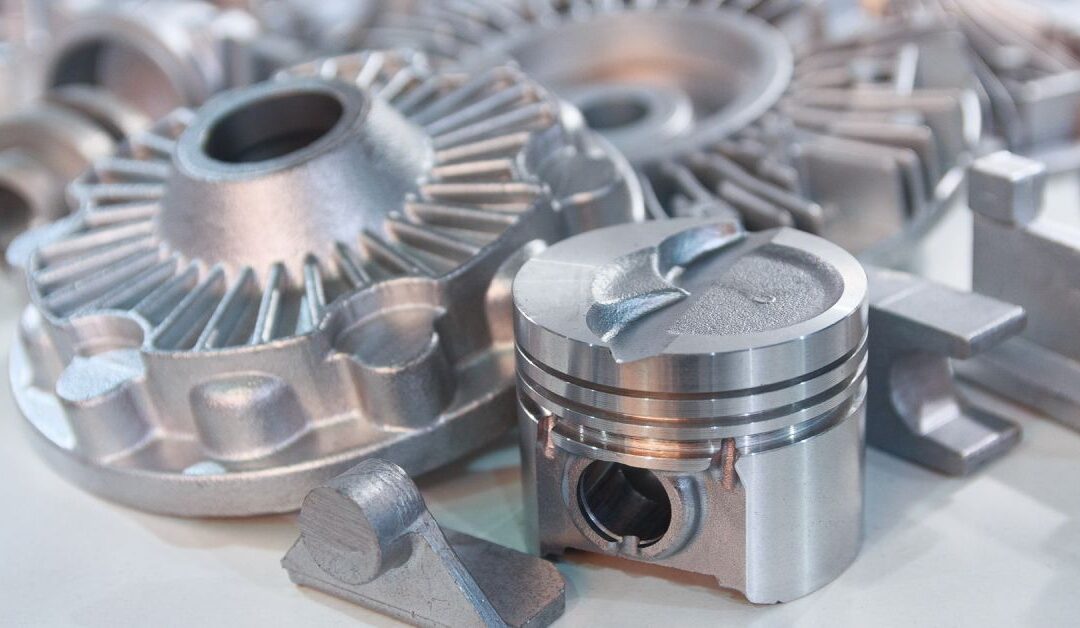

Aluminum Castings 101: Comprehensive Details and High Quality Services for Your Tasks

Aluminum castings give a trusted choice for various markets, offering a special blend of longevity and lightweight qualities. Comprehending the different spreading processes is important for picking the very best approach for details projects. As innovation breakthroughs, the landscape of aluminum casting continues to alter, opening up new opportunities. Exploring the nuances of these techniques reveals essential insights that can affect task results substantially. What aspects should one consider when selecting a casting service?Comprehending Light Weight Aluminum Spreading Processes

Light weight aluminum casting procedures work as a structure for generating a vast array of steel parts made use of in various industries. These procedures entail the makeover of liquified light weight aluminum right into certain shapes with mold and mildews. Usual methods include sand spreading, pass away spreading, and investment casting, each offering distinct advantages based upon the application.In sand spreading, a mix of sand and binder develops a mold, allowing for elaborate designs and better adaptability in production. Die casting uses high-pressure strategies to infuse liquified aluminum into steel molds, leading to precise measurements and smooth surfaces. Financial investment spreading, additionally called lost-wax spreading, enables very outlined parts, making it ideal for complicated geometries.

Comprehending these processes is necessary for makers and engineers to choose the suitable approach for their jobs. Each technique adds unique characteristics to the end product, impacting its performance and viability for specific applications in various industries.

Benefits of Using Light Weight Aluminum Castings

The benefits of utilizing aluminum spreadings are substantial, making them a favored option across numerous industries. Light weight aluminum castings use exceptional strength-to-weight proportions, making certain that parts stay lightweight without sacrificing longevity. This characteristic is particularly beneficial in applications where decreasing weight is important, such as in vehicle and aerospace sectors.Additionally, aluminum's natural corrosion resistance enhances the longevity of actors elements, reducing the demand for safety coverings and upkeep. The versatility of light weight aluminum permits for intricate layouts and shapes, enabling manufacturers to produce intricate get rid of precision.

In addition, light weight aluminum spreadings exhibit exceptional thermal and electrical conductivity, making them excellent for electrical parts and heat-exchanging applications. The reusing capabilities of light weight aluminum additionally contribute to ecological sustainability, as it can be thawed and recycled with marginal power expense. Overall, these benefits highlight aluminum spreadings' raising adoption in contemporary manufacturing procedures, mirroring their performance and dependability.

Typical Applications of Aluminum Castings

Widely identified for their versatility, light weight aluminum spreadings discover application across various sectors, consisting of vehicle, aerospace, and electronics. In the automobile industry, they are frequently utilized for engine components, transmission cases, and structural parts, providing light-weight services that improve fuel efficiency (Wisconsin Aluminum Foundry). Aerospace applications take advantage of aluminum spreadings partially such as brackets, housings, and architectural parts, where strength-to-weight proportion is vitalIn electronic devices, light weight aluminum spreadings work as units and warm sinks, successfully dissipating warmth while giving defense for delicate elements. The appliance industry makes use of light weight aluminum spreadings for numerous components and housings, guaranteeing toughness and aesthetic allure. In addition, the building industry uses light weight aluminum spreadings in attractive functions and architectural components, blending performance with layout. In general, the varied applications of light weight aluminum castings demonstrate their crucial function in modern-day manufacturing, driven by their unique residential properties and versatility to meet industry-specific demands.

Kinds Of Light Weight Aluminum Spreading Techniques

The numerous aluminum spreading strategies each offer distinct benefits matched to various applications. Sand casting is known for its flexibility and cost-effectiveness, while die casting gives superb dimensional precision and surface coating. Financial investment spreading, on the various other hand, is celebrated for its ability to generate elaborate geometries with high accuracy.Sand Spreading Process

Sand spreading stands out as one of the most preferred techniques for light weight aluminum spreading due to its adaptability and cost-effectiveness. This procedure entails developing a mold from sand, which is after that loaded with molten aluminum to produce a desired form. The sand mixture usually is composed of silica sand, water, and clay, giving the necessary stamina and flexibility for mold development. When the molten metal is put into the mold and mildew, it solidifies and cools, after which the sand is eliminated, revealing the actors part. Sand spreading is specifically useful for producing huge parts and complicated geometries. Additionally, it fits reduced production quantities effectively, making it suitable for models and personalized parts. On the whole, sand spreading stays an essential method in the aluminum casting industry.

Die Casting Advantages

Die casting deals a number of benefits that make it a favored selection in the aluminum casting field. This method permits the production of complex shapes with high dimensional precision, decreasing the demand for considerable machining. In addition, pass away casting is characterized by its fast manufacturing price, enabling manufacturers to meet large-volume needs efficiently. The procedure likewise leads to a smooth surface coating, which reduces post-processing requirements. In addition, die casting uses recyclable molds, causing reduced per-unit costs in time. The integral stamina and lightweight residential properties of light weight aluminum boost the durability of the final items, making them appropriate for different applications. In general, pass away casting provides a combination of performance, accuracy, and cost-effectiveness that attract numerous markets.Investment Spreading Precision

Investment spreading is renowned for its precision and ability to create elaborate layouts with tight resistances, making it a highly concerned method in the light weight aluminum casting landscape. This method includes creating a wax pattern, which is coated with a ceramic covering and consequently heated up to remove the wax, leaving a mold and mildew for molten aluminum. The reduced thermal growth of the materials assurances dimensional precision and repeatability in manufacturing. Investment spreading is specifically advantageous for intricate shapes and thin-walled components, which are challenging to achieve with over at this website various other spreading strategies. In addition, the surface finish obtained can typically lessen the requirement for substantial machining, additional enhancing its effectiveness for high-precision elements utilized in various industries, including aerospace and vehicle.Top Quality Control in Light Weight Aluminum Spreading Manufacturing

Quality assurance in light weight aluminum casting production is vital to ensure that items fulfill market criteria and client assumptions. This involves different evaluation techniques and techniques to analyze the integrity and high quality of the spreadings. Furthermore, compliance with established guidelines is important to preserving item safety and performance.

Examination Techniques and Techniques

Efficient evaluation techniques and approaches are crucial for assuring the integrity and performance of light weight aluminum castings. Various approaches are used to find problems and assure top quality throughout the production process. Visual evaluations are generally performed to determine surface area abnormalities, while non-destructive testing methods, such as ultrasonic and radiographic inspections, review interior frameworks without compromising the material. In addition, dimensional evaluations using coordinate gauging devices (CMM) verify that spreadings satisfy defined tolerances. Chemical structure analysis warranties that alloy requirements are satisfied, adding to the total quality. Executing organized sampling and statistical process control assists check manufacturing consistency. By utilizing these varied evaluation methods, makers can promote high criteria, ultimately leading to long lasting and trusted light weight aluminum castings for various applications.

Specifications and Compliance Rules

While adhering to rigorous requirements and compliance policies is crucial in aluminum casting production, it likewise assures that items satisfy market specifications and consumer assumptions. Compliance with criteria such as ASTM, ISO, and SAE assures that aluminum castings possess the needed mechanical residential or commercial properties, dimensional precision, and surface area finish. Makers need to apply quality assurance systems that consist of normal audits, screening, and paperwork to verify conformity. In addition, accreditations such as ISO 9001 demonstrate a dedication to quality monitoring practices. By complying with these regulations, producers can minimize dangers associated to problems and improve product reliability. Ultimately, adherence to developed criteria fosters trust and satisfaction among clients, placing companies positively within competitive markets while advertising constant renovation in manufacturing processes.Picking the Right Light Weight Aluminum Spreading Solution

Just how can one guarantee they pick the most appropriate aluminum casting service for their task? To begin, it is important to assess the company's experience and experience in the specific kind of aluminum casting called for. Reviewing their portfolio can reveal their capability to deal with similar jobs efficiently. In addition, reviewing client reviews and looking for recommendations can supply insights into their dependability and high quality of job.Next, one should think about the series of solutions supplied, consisting of layout support, prototyping, and finishing choices. An extensive company can improve the production procedure and assurance uniformity in top quality. It is essential to verify compliance with market requirements and laws, making specific the service fulfills essential specifications. Metal Castings.

Contrasting and acquiring quotes pricing structures enables for informed decisions while thinking about value over cost. By following these standards, one can with confidence pick a light weight aluminum casting service that fulfills task needs and expectations.

Future Patterns in Aluminum Spreading Modern Technology

As the aluminum spreading industry advances, emerging innovations are readied to improve manufacturing procedures and enhance efficiency. Innovations in additive production, particularly 3D printing, are making it possible for rapid prototyping and lowered preparations. This advancement allows for even more complex layouts that were visit our website formerly unattainable with standard methods. In addition, the assimilation of man-made knowledge and maker understanding is simplifying high quality control, anticipating problems, and enhancing manufacturing schedules.Sustainability continues to be a crucial pattern, with a boosting emphasis on recycling aluminum and decreasing waste throughout casting. Firms are investing in energy-efficient heating systems and procedures to lower their carbon impacts. In addition, wise spreading methods that include my explanation IoT sensors are enhancing tracking abilities, supplying real-time information to improve functional efficiency.

These fads indicate a change towards even more cutting-edge, sustainable, and reliable practices in the aluminum spreading field, ensuring that it continues to be affordable in a rapidly changing manufacturing landscape.

Often Asked Concerns

What Is the Common Preparation for Aluminum Casting Projects?

The common lead time for light weight aluminum casting projects ranges from 4 to 8 weeks, depending upon factors such as style intricacy, production quantity, and the producer's capabilities, making certain top quality and prompt delivery to clients.Exactly how Do I Determine the Right Alloy for My Task?

To determine the appropriate alloy for a job, one should review mechanical buildings, corrosion resistance, thermal conductivity, and designated application. Consulting with experts and referencing material requirements can direct the option process effectively.Can Light Weight Aluminum Castings Be Recycled After Usage?

Yes, aluminum spreadings can be reused after use. The reusing procedure is effective, saving power and sources. This lasting practice helps lower ecological influence while promoting a circular economy within the steel industry.What Are the Price Aspects for Light Weight Aluminum Spreading Services?

Exist Environmental Regulations Related to Aluminum Casting?

Yes, there are environmental laws associated with aluminum spreading. These regulations intend to reduce emissions, manage waste, and guarantee sustainable methods, calling for producers to follow rigorous standards to secure water, air, and land high quality.Sand spreading is understood for its convenience and cost-effectiveness, while die spreading supplies outstanding dimensional precision and surface coating. Sand casting stands out as one of the most prominent methods for light weight aluminum spreading due to its adaptability and cost-effectiveness. Investment spreading is renowned for its accuracy and capability to generate complex layouts with tight resistances, making it a highly regarded strategy in the aluminum spreading landscape. Financial investment spreading is specifically advantageous for complicated shapes and thin-walled components, which are challenging to achieve with various other casting methods. As the aluminum casting market develops, emerging modern technologies are established to improve production processes and boost effectiveness.

Report this wiki page